Technical Matter

DEVELOPMENT OF NEW PRODUCT

- Comparing as per customer Assembly drawing with actual sample important dimension & finalize Assembly drawing.

- Bifurcation of all components on process based & making Pattern & Dies & drawing of Individual components.

- Making list of tooling for Machining, Boring, Drilling in a conventional & C.N.C/V.M.C set up & Detail operation sequence for individual components for work shop.

INSPECTION

- All Machined components are inspected as per drawing size with various Measuring Instruments & all non critical items are inspected on sampling Basis.

- All Casting / Aluminum housing components are inspected by air & water pressure & Proper flow passage.

- Proper inlet & outlet water circuit position from mounting surface.

- Extensive use of Corrective & Preventive process control.

- Various important parameters of components like chemical composition, material are get it inspected from outside.

ASSEMBLY

- Height of Pump, Height of Pulley/Hub, Height/Depth of Impeller from pump face.

- Fitting of Boll Bearing/ Integral Shaft Bearing in shaft/housing & fitting of seal considering material & size for uniform pressure.

- In pump assembly face of pump is flat for better stick ness of gasket.

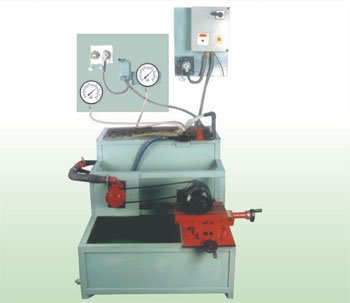

TESTING

- We make pump testing fixture with proper Outlet & Inlet for Endurance test for wear out of Moving components & for routine testing.

- Testing in temperature up to 100 c discharging 40 to 200 lit/min of flow with 8 to 15 PSI pressure & up to 4000 RPM with air & water / oil with torque.

- Testing of pump for noise level.

Inspection & Laboratory

We have all critical measuring instruments, for inspection of components, hardness tester, surface plate between center, mechanical comparater stand, spring load tester, digital tachometer, digital height gauge, crack dector, air testing unit, microscope for micro structur of material & various othr testing facility.

We do follow various Std. & parameters for our pump components

BALANCING

Moving parts of water pump assembly as pulley and impeller are dynamically balanced to avoid uneven load on bearing and seal assembly during running as per ISO 1940 Std. according to pump object weight & rpm of pumps to remove unbalance mass of object.

TESTING

Testing in temp as high as 100c discharging 40 to 200 lit/min of flow with 8 to 15 PSI pressure and 4000 RPM of any water pump for leakage. We do endurance test with uttermost precision to check the life of moving component & wear out of pumps with different parameters.

Finally our design department helps the production department to meet changing demand of its customers satisfaction at every stage.

List of Machines

| Sr no. | Type of machines | Specification of machines | Make of machines | Nos. of machines |

| 1 | CNC-Turning Center Model :- Jobber J-300LM |

Max Turning Dia :- 320mm Max Turning Length:-300 mm Speed Range:- 4000 RPM Max Bar Capacity :- 42 Control System:- Fanuc |

ACE Micromatic | 4 |

| 2 | CNC-Turning Center Model:-DX-200-5 |

Max Turning Dia :- 350mm Max Turning Length:-500 mm SSpeed Range:- 50-4000 RPM Max Bar Capacity :- 52 Control System:- 828 Siemens |

Jyoti (Collobrated with Huron France) | 2 |

| 3 | CNC-Vertical Machining Center VMC-1050/td> | Stroke :- X- 1020 mm Y- 510 mm Z- 510 mm Max Spindle RPM :- 8000 Nos. of tools capacity :- 20 nos.. Max. axis Rapid :- 24 m/min Max. spindle power :-15/11 Kw |

Jyoti (Collobrated with Huron France)) | 1 |

| 4 | CNC-Vertical Machining Center Model :- ACER-50 |

Stroke :- X- 800 mm Y- 510 mm Z- 500 mm Max Spindle RPM :- 6000 Max. axis Rapid :- 24 m/min Max. spindle power :-15/11 Kw |

ACE Micromatic | 1 |

| 5 | CNC-Fourth Axis in VMC | Center height of take :-250 mm Load carrying capacity:-175 Kg |

UCAM (Banglore Make-Indian) | 1 |

| 6 | CNC-Turning Center Model:-Linear Slant Bed-640 |

Max Turning Dia :- 150mm Max Turning Length:-280mm Speed Range:- 3000 RPM |

Real tech CNC | 3 |